Risk Ranking

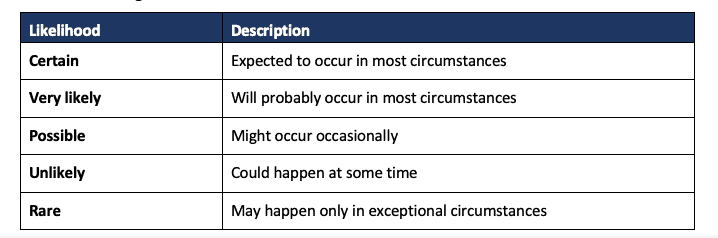

The final step is to assess the overall risk of exposure to assist in deciding which controls are appropriate and how quickly they need to be applied. There are risk rating matrices available internationally to assist with ranking the risks using categories such as: extreme, high, medium, and low risk.

Note: All asbestos carries a health risk until it is safely disposed of

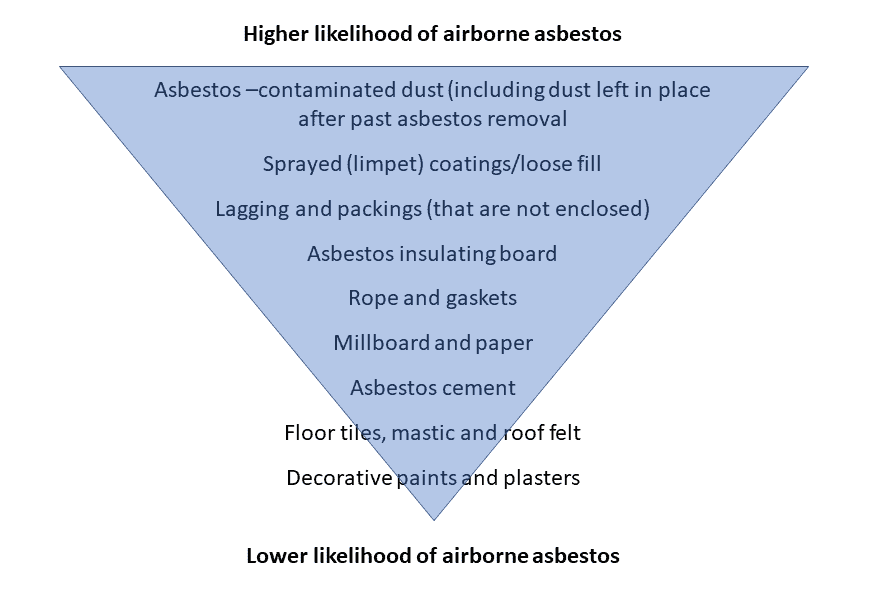

Rank the products from the highest risk of releasing fibers to the lowest. This ranking enables prioritization for implementation of control measures to the highest ranked ACMs first.

Control the Risks

Hierarchy of control measures

The hierarchy of control measures orders the most effective ways to control risks at the top to the least effective at the bottom:

- Eliminating the risk (removing/substituting the asbestos)

- Isolating the risk or applying engineering controls (for example, enclosing, encapsulation, sealing)

- Using administrative controls (for example, safe work procedures, using appropriate tools and training)

- Using personal protective equipment (respirators, disposable gloves, goggles, coveralls)

The ACMs rated the highest risk of releasing fibers should be eliminated from the workplace by professional removal as soon as possible.

The preferred outcome for all ACMs is to eliminate the risk of asbestos exposure by removing it from the workplace. However, if it is not possible, or if it is in good condition, then the other controls for minimizing the risk should be considered.

Other than elimination, a combination of these controls may be required in order to adequately manage and control asbestos or ACM.

Eliminating the risk – Removing asbestos

Even where asbestos is contained or in good condition, there is always a risk of fiber release until the ACMs are removed and disposed of by burial in a landfill.

Asbestos must be removed and disposed of by qualified and trained professionals and in accordance with all workplace laws.

Examples of where removal may be the best control measure include:

- asbestos lagging on pipes in moderate condition in a high-traffic area

- asbestos-contaminated dust (ACD) in areas accessible by people

- loose fibre insulation in ceilings is highly friable and should be prioritised for removal

- cracked or damaged fibreboard containing asbestos in an open area

Managing asbestos in place – isolation and engineering controls

Where it is not reasonable for asbestos be removed, it must be managed to minimize the risk of asbestos fibers being released. Using the hierarchy of controls, this may be done through a combination of the remaining control options – isolation/engineering, administrative and personal protective equipment controls.

Isolating the risk – Enclosing, encapsulating, or sealing asbestos

Where it is not reasonably practicable to remove non-friable asbestos that is in good, fair, or medium condition, the preferred alternative control measure is enclosure.

What is enclosure?

Enclosure involves building a solid structure (such as using plywood) around the asbestos to protect it from damage and inadvertent access. The structure needs to:

- allow regular inspection of the ACM’s condition

- prevent impact to the ACM – e.g., an enclosure of an asbestos cement wall in a warehouse may also require protective bollards to prevent accidental forklift impact of both the enclosure and ACM.

If the asbestos cannot be removed or enclosed, encapsulation or sealing will be the next appropriate control measure.

What is encapsulation?

Encapsulation means binding asbestos in a resilient compound to minimize the release of fibers. Examples of encapsulant compounds include reinforced plastics, vinyls, resins, mastics, bitumen, flexible plasters and cements. Encapsulation will bind loose fibers into place and should be used only when the original asbestos bond is still intact.

Encapsulation helps protect the asbestos from mechanical damage and can be used as an interim measure to extend the life of an asbestos product until it can be safely removed. Encapsulation can also be used to strengthen asbestos materials during removal.

What is sealing?

Sealing is the process of covering the surface of the material with a protective coating. This only covers the material to minimize asbestos fiber release. This is opposed to encapsulation where the compound binds the asbestos fibers within the compound.

Speak to suppliers and experts to select a suitable coating for the material and its use. The coating (sealant) may deteriorate if it is exposed to chemicals, extreme heat or cold, wet or dry conditions or physical impacts. The ACM’s location may require the sealant to provide fire resistance, thermal insulation or ultraviolet (UV) protection.

Choosing a different colored sealant to the underlying asbestos can ensure complete coverage during application and assist with monitoring its condition over time.

The surface on which the sealant is to be applied should be cleaned first with:

- a low-pressure hose and then left to dry

- a HEPA filtered H-Class industrial vacuum cleaner (not an ordinary house-hold vacuum-cleaner) or

- a wet disposable cloth

These actions capture any loose dust or debris from the surface and ensure good adhesion of the sealant. Do not use sandpaper to prepare the surface.

Apply the sealant using an airless sprayer at low pressure. Several coatings may be needed for full protection. Rollers and brushes should not be used because they cause abrasion or damage to unsealed asbestos and result in fibers being released.

Administrative controls

These controls help employees and contractors know where asbestos is, what to do to prevent fiber release and what to do in an emergency. Administrative controls include asbestos registers, signs, training, emergency procedures and safe work instructions. Examples include:

- guidance on what tools should be used on or near ACMs

- signage not to use power tools on or near the asbestos

- procedures for operating machinery near ACMs

Personal protective equipment

The provision of personal protective equipment (PPE) is the last line of defense to protect workers if fibers are released by the work they are doing. PPE relies on workers wearing it correctly and is only effective if it fits properly and is used according to the manufacturer’s instructions.

Develop of Asbestos Management Plan

An Asbestos Management Plan sets out how the identified ACM will be managed to prevent or minimize risks to health of workers and others.

An Asbestos Management Plan includes:

- a reference or link to the Asbestos Register

- the risk rating for asbestos fibre exposure and control measures for each identified ACM

- decisions, and reasons for the decisions, about the control measures applied

- prioritised schedules for implementing control measures including removing asbestos

- schedules and procedures for monitoring and reviewing:

- the condition of each ACM

- the Asbestos Register

- asbestos control measures

- the Asbestos Management Plan

- procedures for responding to accidents, incidents or emergencies of asbestos exposure

- procedures for carrying out work involving asbestos

- how and what information and training will be provided to workers and contractors regarding the health hazard of asbestos, prevention of fibre release and location of asbestos at the workplace

- identification of persons responsible for taking action under the Asbestos Management Plan.

Once implemented, the Asbestos Management Plan should be reviewed annually to:

- assess whether the ACM’s condition has changed

- ensure the controls are still effective.

The Asbestos Management Plan remains active for as long as there is asbestos in the workplace. To keep it up to date and effective, it should also be reviewed whenever asbestos has been damaged, removed or repaired.

When arranging for professionals to carry out any demolition or refurbishment work, the person with management or control of the workplaces should:

- review the asbestos register to ensure it is up to date

- provide a copy of the asbestos register to the person carrying out the demolition or refurbishment before the work starts

- ensure asbestos that is likely to be disturbed is identified and either removed or protected before the demolition or refurbishment starts (if asbestos removal is not part of the work).

After any demolition or refurbishment work is complete, the Asbestos Register and the Asbestos Management Plan should both be updated.

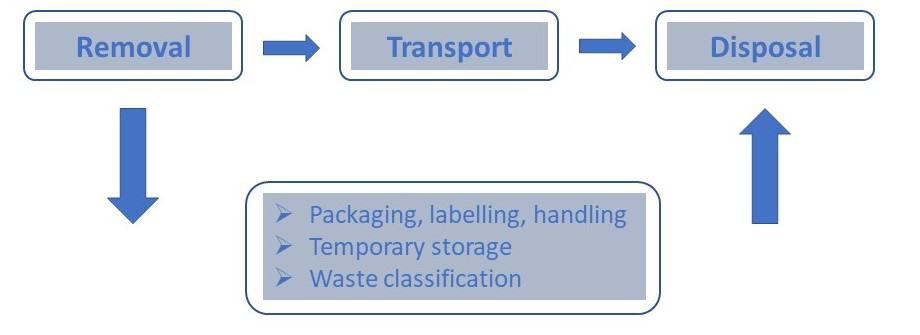

Environmental and transport laws

The primary focus of environmental and transport laws is to prevent the pollution of the environment. The transport and disposal of asbestos must be done in accordance with those laws.

Asbestos waste life cycle